The world of manufacturing is undergoing a transformation, driven by innovation and sustainability. In an exciting project led by RISE Research Institutes of Sweden, ADAXIS helped push the boundaries of traditional manufacturing further than ever before. The project demonstrated how large-scale additive manufacturing and industrial robotics can be used to 3D print and machine a full-sized kayak using recycled materials.

The design of the kayak, known as the Värmdö kayak, was created by Melker of Sweden and optimized for the robotic additive manufacturing process by the team at RISE. The final design was printed using a high throughput pellet extruder attached at the end of a ABB IRB6700 robotic arm.

The materials used is a great real life example of a circular material flow. It is based on an old recycled kayak that had been previously 3D printed at RISE. The original kayak was in turn made from recycled polyethylene wood fiber composite (FibraQ from Biofiber Tech Sweden AB) and shredded and combined for this print using RISE in-house recycling facilities.

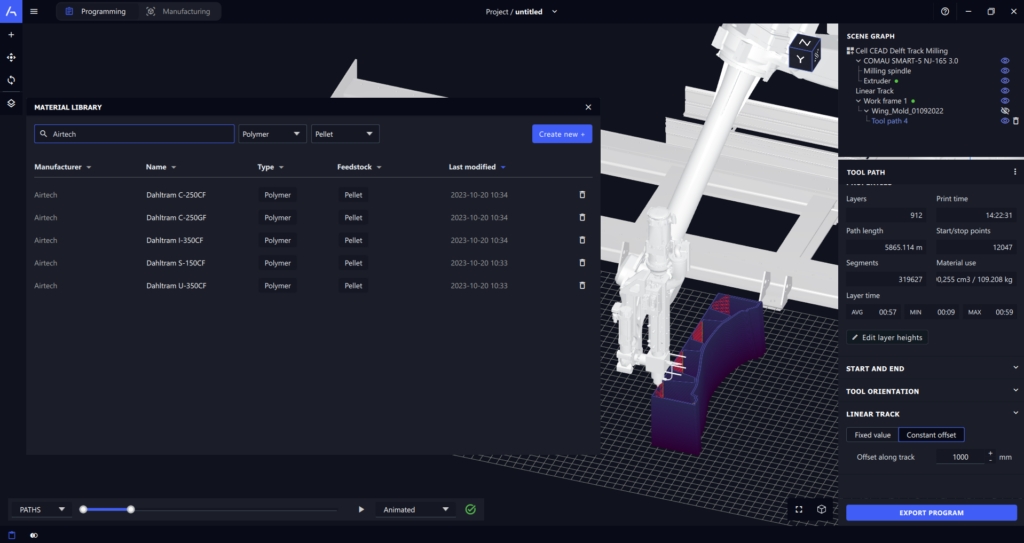

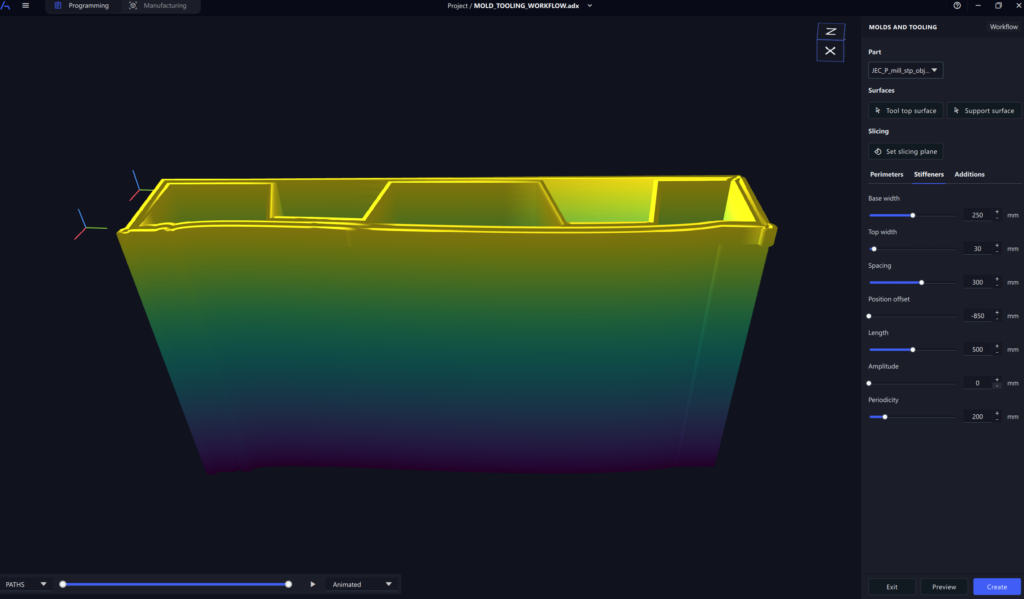

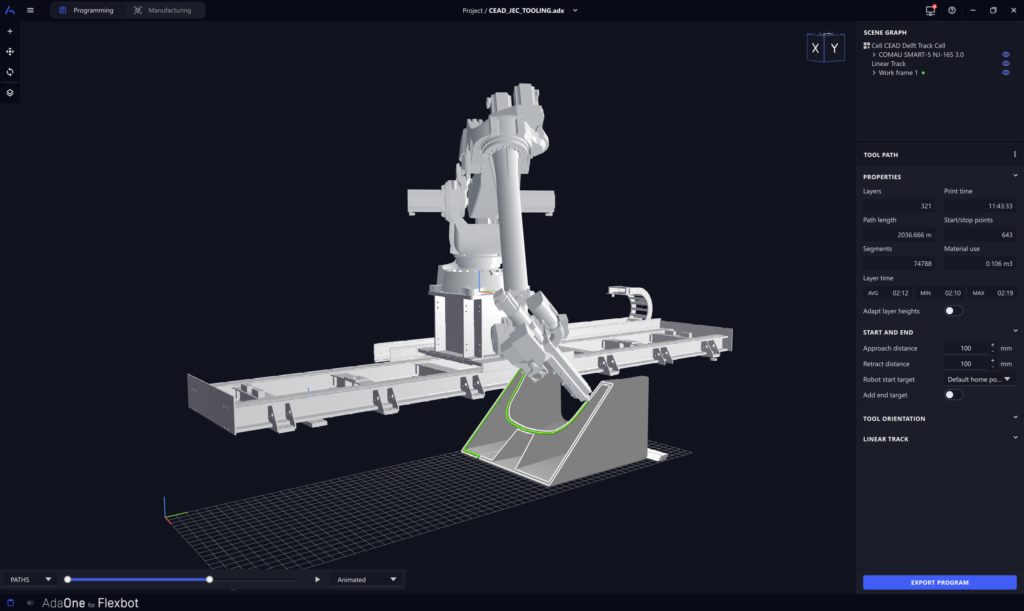

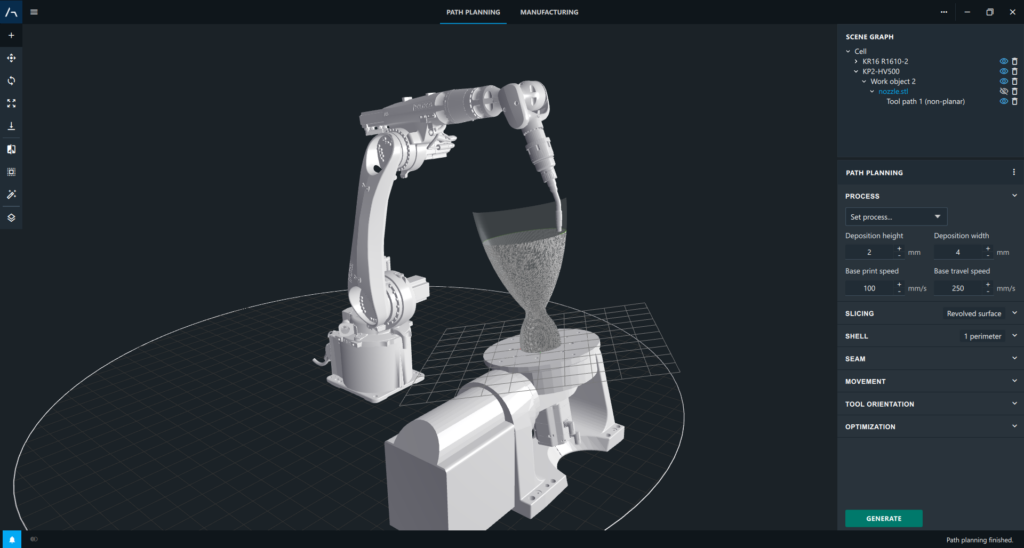

ADAXIS AdaOne software was used to generate tool paths for both the additive manufacturing and subsequent machining. Tool paths generated at a 45-degree angle was used, enabling a continuous and seamless printing process. The final steps involved creating milling paths to open all hatches, drill holes, and mill the hull bottom. Again, all milling, drilling and cutting was created by and controlled from AdaOne.

This project unveiled several innovative sub-processes, such as printing on hatch rings. Printing on previously printed non-planar surfaces opens up interesting possibilities, but it’s not without its challenges. How to make the new print adhere to the previous print, particularly when it’s no longer a continuous process, remains an area of ongoing research.